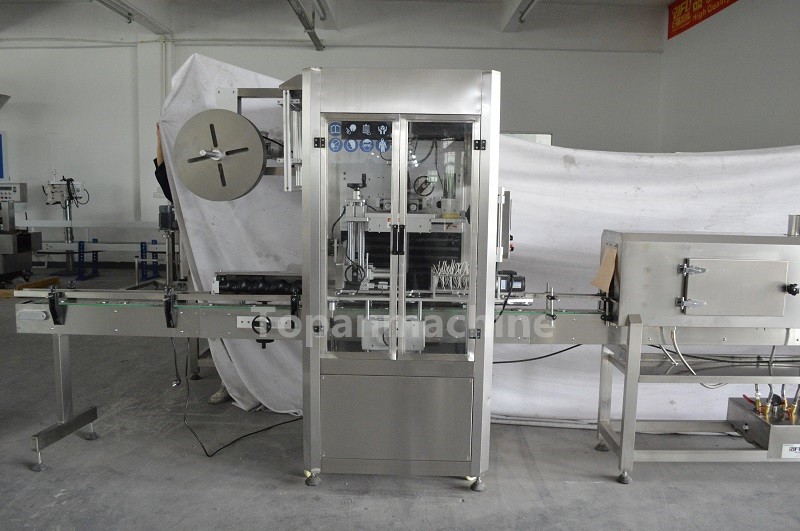

Topan Automatic Heat Shrink Sleeve Label Wrapping Machine description

The set of marking machine is suitable for a wide range of industries, products, mainly suitable for a variety of containers bottles, containers, a variety of shapes and

Shrink film packaging of materials (such as: food and beverage, cleaning supplies, medicines, makeup and other plastic bottles, glass

Bottles, PVC, PET, PS, cans and other containers), can be fully connected with the production line and single operation, empty

Bottle or filling can be packed and used, automatic and fast packaging, saving a lot of labor costs, while greatly improving

The packaging effect of the product.

Topan Automatic Heat Shrink Sleeve Label Wrapping Machine features:

1. Significantly reflects the double effect of efficiency and benefit after replacing manual marking;

2. Require simple operation, with a certain automatic detection function, failure can alarm;

3. Simple operation, man-machine interface adjustment;

4. The equipment should be stable and reliable;

Product (bottle feeding)→ plate chain conveyor conveying → bottle splitting and bottle bearing mechanism simultaneously parting and correcting position → electric eye

Detection → The marking mechanism receives the electric eye signal to cut the mark → the label is quickly positioned and sent to the specified part of the bottle on the product

Point → Label position correction → Heat shrink label.

The main processes of sending and setting tenders are detailed as follows:

Stretch -- fixed length -- cut off -- pull -- set label -- label positioning -- shrink -- finished product

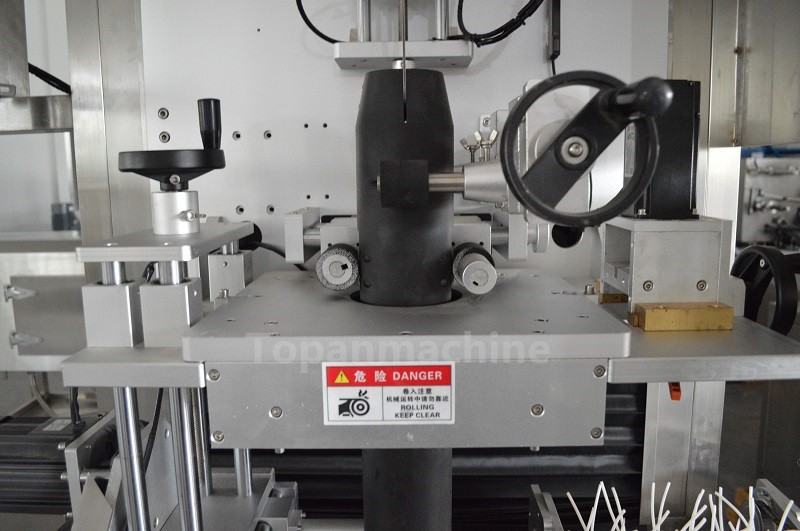

Components of the marking machine:

Feeding and front conveying: plate chain conveying device

Power label uncoil

Set of bid parts: bid sending system, cutter head, finishing mechanism, traction bidding mechanism

Servo motor and PLC control system according to the actual requirements of the position closed loop, speed closed loop

The control and quick trigger response mechanism realize the needs of the bidding machine when sending and cutting the bidding

High precision positioning, high-speed stable operation requirements.

When the product is uniformly transported to the marking position, the electric eye of the measuring object detects the product and immediately starts to cut the mark

A mechanism that makes the label cut to the desired height and simultaneously moves downward under the action of a pushing roller,

Reach the top of the product to accurately cover the label.

Label insert positioning guide mechanism: make the label accurately insert, and lift to the specified position

Electrical control part: PLC, high-sensitive electric eye and other electrical components and human-machine interaction interface software and contact

Control screen composition. Realize the integrated control of the system.

Topan Heat Tunnel Shrink Wrapper Packing Machine Structural advantages:

1).Compact fuselage design, high-performance mechatronics control operation unit, humanized flexible operation

2).The mature servo control system ensures the reliability and agile control performance of the equipment to the maximum extent

3).The current set of standard has high precision, high speed, high stability, perfect and flat shrinkage, simple operation and complete functions.

4).Conveyor belt, material separation, product correction mechanism, marking mechanism are driven by a separate motor, and can be stepless

5).Frequency conversion speed regulation, with the sleeve speed, so that the sleeve and shrinkage can be flawless.

Topan Automatic Heat Shrink Sleeve Label Wrapping Machine features:

1).Intelligent control - with the function of automatic detection of labels and products, to achieve uniform and synchronous speed of the whole machine.

Make the operation more simple and humanized.

2).Man-machine dialogue touch screen - with human touch control screen, full Chinese/English or Customized display, not only operation

3).It is simple, intuitive, fully functional, and has rich help functions and fault display functions.

4).Label parameter storage - preset multiple sets of label parameters, change the product without re-setting (label processing long

5).The degree is adjusted according to the needs of product packaging), that is, it has the function of memory storage program and can be ordered for different programs

Rank #. Replace different specifications or use different production capacity, just adjust different parameters, do not have to be again

Adjust, greatly improve work efficiency.

6).The whole system adopts PLC control - to maintain the coordination and stability of the whole machine operation.

7).With detailed self-test function - can be on various I/O, RAM, EEPOM, indicator light, LCD display

8).Various functions of the screen are self-checked, and the fault display will show the fault.

The working state and fault of the machine have a warning function to make the operation and maintenance more convenient.

9).The electrical components of the whole machine are mainly imported brands, such as: inverter (Tai 'an), PLC (Omron), Wait

Service system (Delta), photoelectric device (Panasonic), electrical switch (Panasonic), touch screen (Omron), etc.

Our goal is to use the parts that we think are most suitable for customers and can ensure the supply of goods; It's really solid

Performance and stability are implemented on every component and part.

10).All parts including the bottom cabinet, conveyor belt, stop rod and small screws are made of stainless steel and aluminum profiles

Production, never rust, no pollution, to ensure compliance with GMP environmental requirements.

11).After the replacement of the product, as long as the central guide pillar of the corresponding product is replaced, it can be working well

after simple debugging

Topan Automatic Heat Shrink Sleeve Label Wrapping Machine Parameters

|

Bottle dia. |

φ25 ~φ56mm(A),φ56~φ86mm(B),φ86~φ106mm(C),φ106~φ125mm(D) or Customized |

|

Label length |

25 mm~300 mm |

|

Conveyor width |

102mm |

|

Inner diameter of paper tube:

|

5 "~ 10" is applicable |

|

Power |

AC380V,50/60HZ,3phase or customized |

|

Speed |

100B/min |

|

Power |

Main engine 3KW;Shrink furnace: Shrink furnace 12/24kw |

|

Relative temperature of use environment |

0-50 ° C |

|

Relative humidity of use environment |

15% – 90% |

|

Main machine size |

L6000mm*W1055mm*H2000mm |

|

Main machine weight |

About 600kgs |

Topan Automatic Heat Shrink Sleeve Label Wrapping Machine Details

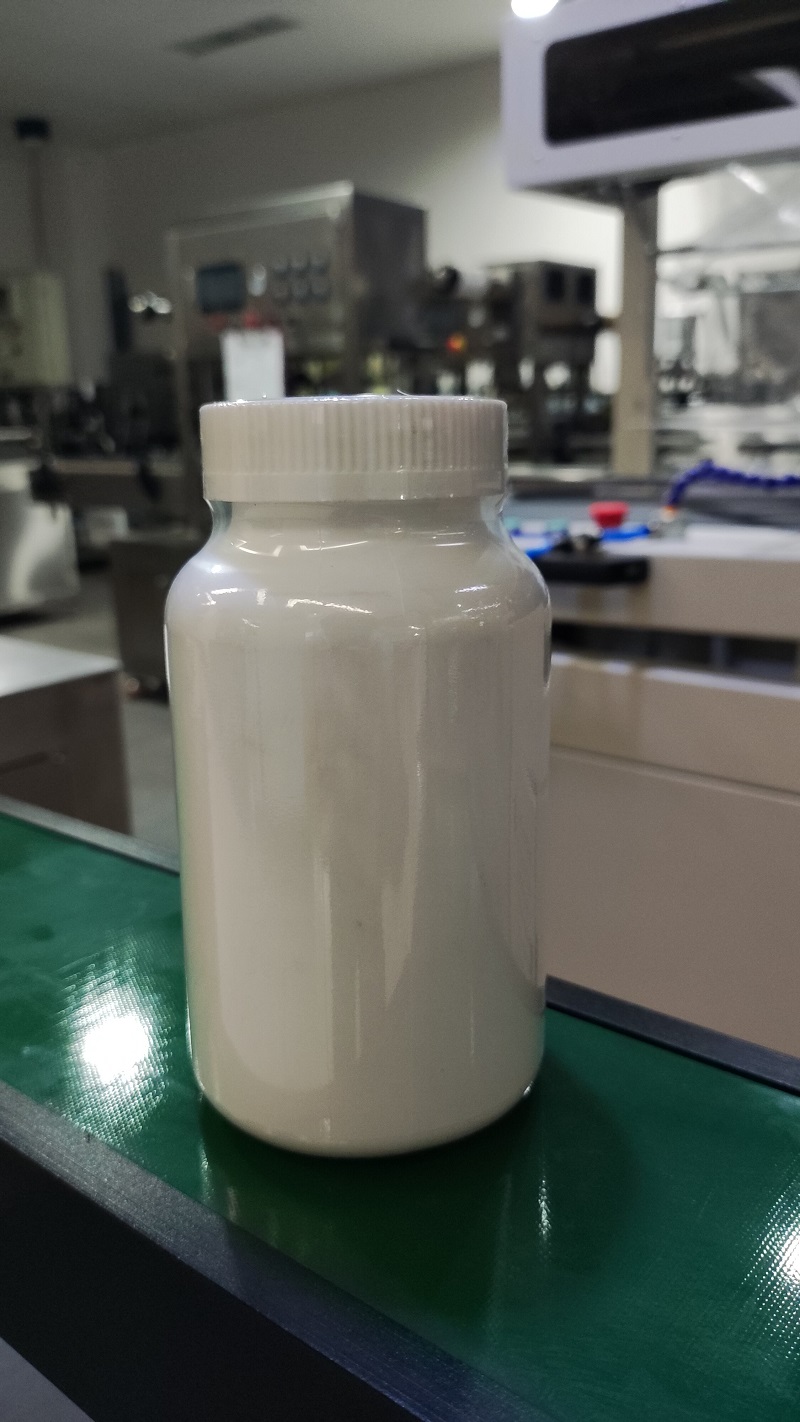

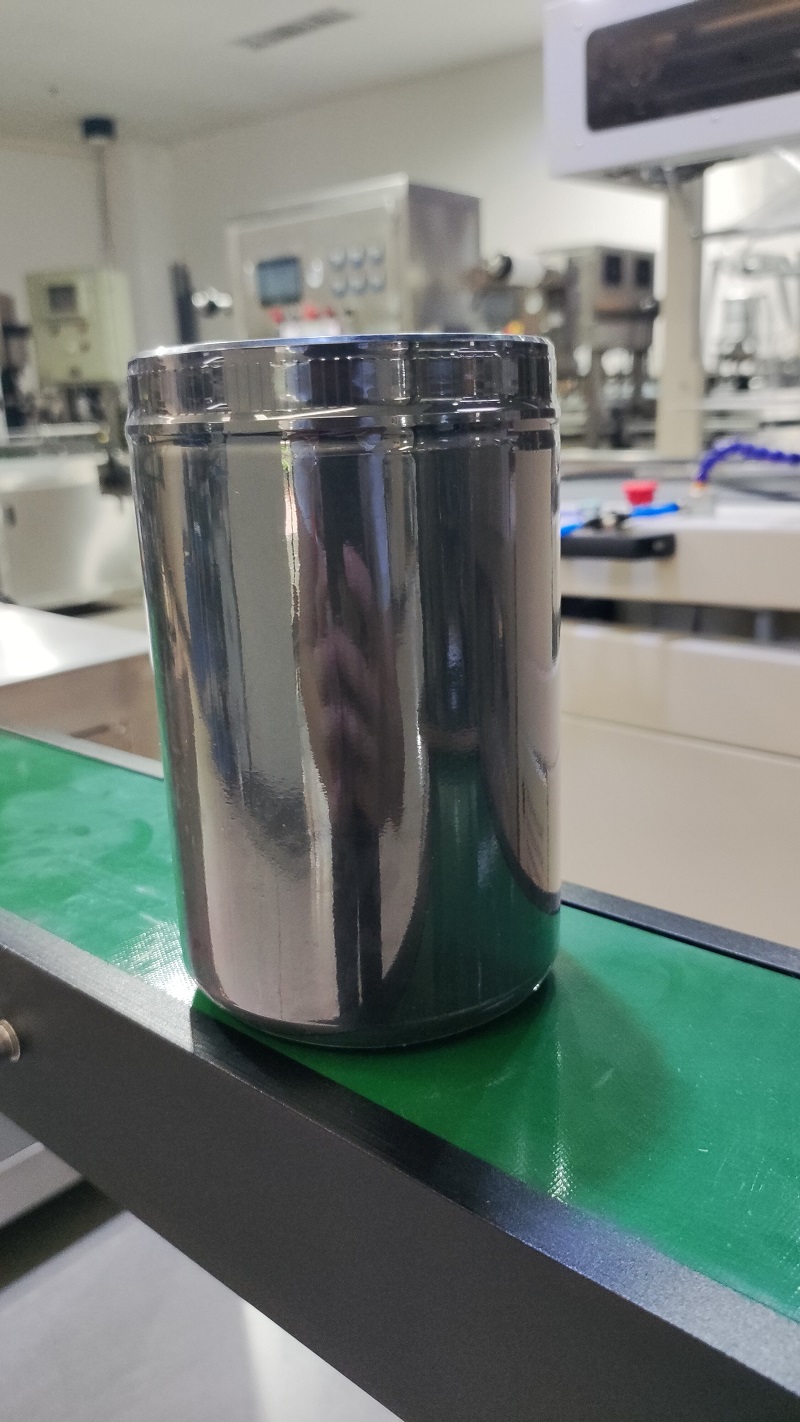

Topan Automatic Heat Shrink Sleeve Label Wrapping Machine Packed Bottles

The Answers Clints Care About Topan Shrink Wrapping Machine

1).Heat Tunnel Shrink Wrapper Packing Machine is customized according to the clients' bottles, the machine can be used for different bottles by gide pillar

2).For ToPan Shrink Wrapping Machine, we provide you 12 months qualiy warranty, life time service.

3).Free training of machine installation,operation and maintenance will be provided by our engineer.

4).Some spare parts and tools will be sent with the machine for free.It’s available to buy the parts from us forever at low price.

5).We’ll support customers 24 hours after-sale forever by call,email and video etc.

6).Our engineer is available to go to the customer’s factory for machine installation and adjustment if necessary.

7).Most of the Shrink Wrapping Machine are installed well before shipping , rest parts will be offered you the installed videos and manual

with the machine

8).Votage can be 220v,380v or customized motors according to the clients' requests

9). Topan Shrink Wrapping Machine lead time is 25 working days normally, customized machine will be about 35 working days.

10).If you are fist time buying goods from China. We can ship the machine to your neareast sea port or DDP to your address.

11). Topan can be customized you the Shrink Wrapping Machine related package shrink film too.

More details about Topan Shrink Wrapping Machine,pls no hesitate to contact us!

Lisa Pan